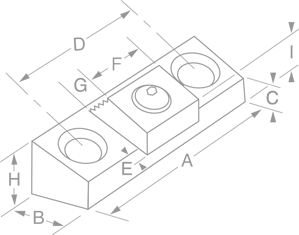

Compact Toe Clamps

This cam action fixture clamp provides positive down force while using very little space on a fixture. Work pieces can be clamped in series by using the back surface of a clamp to locate the next work piece.

The hardened steel clamping element has both a smooth surface for machined work pieces and a serrated clamping surface for rougher work. The height of the clamp can be adjusted by milling the slot deeper in the fixture plate.

Inch

| Part No. | | A | B | C | D | E† | F | G | H | I* | Cam

Screw | Total

Distance of

Movement | Mounting

Screws

(Included) | Torque

(ft/lbs) | Holding

Force

(lbs) | Repl.

Cam Screw | Repl.

Square Washer |

|---|

| 24106 |

|

1.70 |

.75 |

.50 |

1.00 |

.090 |

.75 |

.25 |

.62 |

.845 |

10370 |

.050 |

5/16 – 18 x 3/4 LHCS |

20.8 |

2000 |

10370 |

21006 |

| 24108 |

|

2.12 |

1.00 |

.45 |

1.32 |

.110 |

1.00 |

.38 |

.62 |

.960 |

10372 |

.100 |

3/8 – 16 x 3/4 LHCS |

65.0 |

4000 |

10372 |

21016 |

| 24110 |

|

2.95 |

1.50 |

.99 |

2.00 |

.130 |

1.50 |

.50 |

1.25 |

1.70 |

10376 |

.100 |

1/2 – 13 x 1 1/4 SHCS |

100.0 |

6000 |

10376 |

21026 |

E† – The distance needed between the front of the clamp base and the work piece

I* – The distance from the top of the washer to the bottom of the clamp body.

Drill and tap the centerline of “B” for mounting holes.

Metric

| Part No. | | A | B | C | D | E† | F | G | H | I* | Cam

Screw | Total

Distance of

Movement | Mounting

Screws

(Included) | Torque

(N.m.) | Holding

Force

(N.) | Repl.

Cam Screw | Repl.

Square Washer |

|---|

| 54110 |

|

43.2 |

19.0 |

12.7 |

25.4 |

2.3 |

19.0 |

6.4 |

15.75 |

21.5 |

50368 |

1.6 |

M8x16 LHCS |

28.20 |

8900 |

50368 |

21006 |

| 54112 |

|

54.0 |

25.4 |

11.4 |

33.5 |

2.8 |

25.4 |

9.7 |

15.75 |

24.4 |

50372 |

2.0 |

M10x20 LHCS |

88.13 |

17800 |

50372 |

51016 |

| 54116 |

|

75.0 |

38.1 |

25.2 |

50.8 |

3.3 |

38.1 |

12.7 |

31.75 |

43.2 |

50374 |

2.5 |

M12x30 SHCS |

135.58 |

26700 |

50374 |

21026 |

E† is the distance needed between the front of the clamp base and the work piece.

I* The distance from the top of the washer to the bottom of the clamp body.

Drill and tap the centerline of “B” for mounting holes.