See some design tips here for CNC Machining!

While manufacturing in Canada is our top priority we understand that sometimes clients require production capabilities of overseas manufacturers. Our expertise ensures that wether made Local by us or abroad through our partners we ensure a hassle free experience and competitive pricing – all while meeting tight delivery deadlines.

We take on all responsibility for your satisfaction and ensure your parts meet your requirements. If something is not right, we will ensure it’s corrected immeditely. Period.

Lockhart Precision provides added value by taking on the many risks and responsibilities associated with producing goods overseas. We’re like a general contractor. We not only purchase the raw material to build your tooling, jigs and mechanical parts, but also manage the bill of materials for mechanical assemblies and all related procurement, quality control, logistics, packaging and shipping needs.

Precision CNC Parts From One-off to mass production

Using our 3,4 and 5-axis CNC machines and partners overseas, our machinists can make milled and turned parts in aluminum, stainless, brass, titanium, mild steel, various plastics and wood.

• 3D Modeling

• Design Review

• 3,4 and 5-axis CNC Machining

• Prototyping in Aluminum, Mild Steel, Plastics or Wood

• Surface Finishing

• Inspection

• Packaging

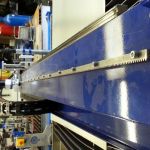

Custom Metal Extrusions

Our extrusion partners ensure fast and affordable custom metal extrusions. Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed through a die of the desired cross-section. The two main advantages of this process over other manufacturing processes are its ability to create very complex cross-sections, and to work materials that are brittle, because the material only encounters compressive and shear stresses. It also forms parts with an excellent surface finish. Lockhart Precision will have the custom extrusion dies made, ensure the profile gets extruded within tolerance followed by secondary processes such as CNC machining, surface finishing and assembly if required

• 3D Modeling

• Design Review

• Tooling Design

• Procurement of Tooling & Production Materials

• Tool Making

• Sample Approval & Optimization

• Inspection

• Surface Finishing

• Packaging

See below for some of the finishes we offer.

Your Parts, Our Solutions

No matter what finish you require, our specialists ensure we achieve the perfect finish for your parts.

• Anodizing

• Electro Plating

• Cerakoting

• Powder Coating

• Laser Engraving

• Glass Bead Blasting

• Sand Blasting

• Polishing

Mechanical Assembly and Packaging

From Concepts through to Design, Manufacturing, Finishing, Assembly, Packaging and even Delivery; Let Lockhart Precision handle all the logistics.

We make your internal processes not only more efficient, but also more cost effective by managing the complexities from start to finish .

• Engineered Drawings

• 3D Modeling

• Technical Documents

• Production

• Sample Approval & Optimization

• Inspection

• Product Artwork / Graphics

• Packaging

• Freight Forwarding

Each part has an optimal production method. We work with our clients to advise and assist with the selection of the most efficient process for each part they require. Our connections and expertise allow us to handle all the back end work while you focus on marketing your products.