Services

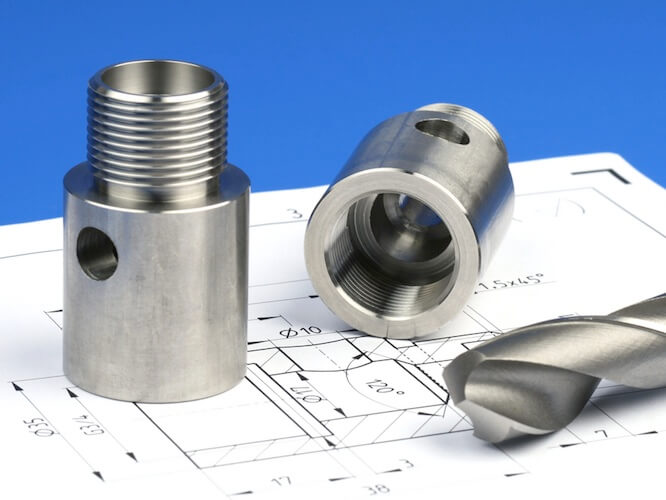

Computer Numerical Controlled (CNC)

CNC Plasma Cutting @ 125/hr

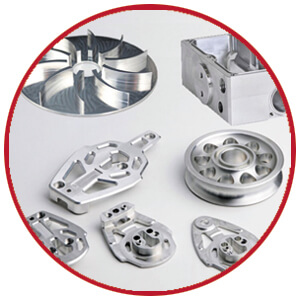

3 Axis 3D CNC Milling @ 125/hr

4 Axis 3D CNC Milling @ 130/hr

5 Axis 3D CNC Milling @ 150/hr

Do you have a large job that you'd like a fixed price on? Call us for a quote!

email at Info@LockhartPrecision.ca or by phone (250) 715-7290

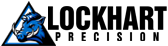

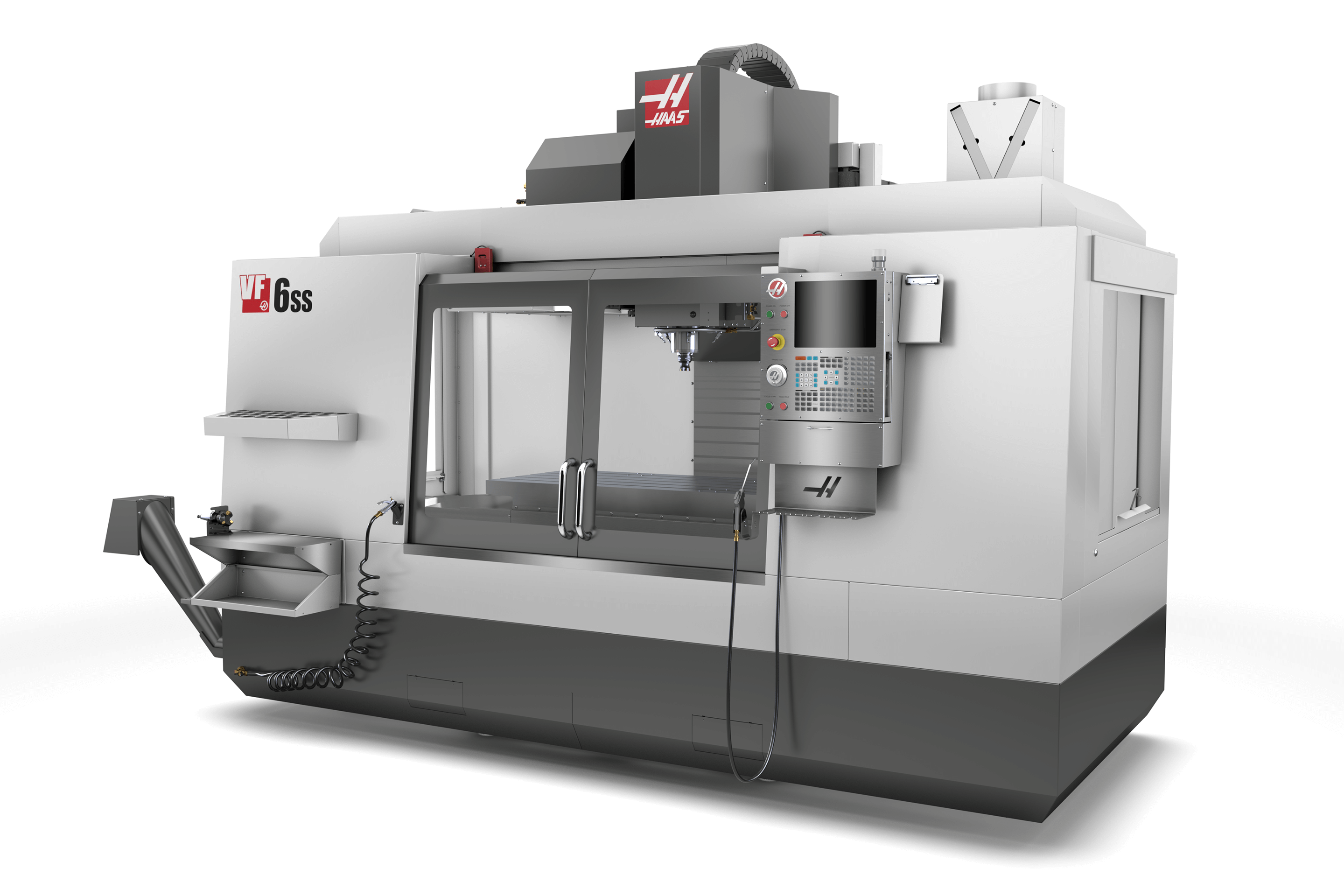

Our state of the art HAAS CNC machining centers are ready to handle simple to complex parts with speed, precision and accuracy.

|

Through Coolant: Yes Tool Capacity: 51 No. Axis: 5 Travel X: 64" Travel Y: 32" Travel Z: 30" Spindle RPM: 15K |

Through Coolant: Yes Tool Capacity: 31 No. Axis: 4 Travel X: 30" Travel Y: 16" Travel Z: 20" Spindle RPM: 12K |

Through-Spindle Coolant

Through-Spindle Coolant

Our Haas Through-Spindle Coolant system provides up to 1000 psi (69 bar) of coolant to the cutting tool, allowing for heavier cuts, higher feedrates, deep-hole drilling, and better surface finishes. With Through-Spindle Coolant, we can really reduce your cycle times and produce higher-quality parts.

What this means for you:

- Allows deep-hole drilling without pecking to reduce cycle times - saving you money

- Reduces material work hardening and increases tool life

- Produces better surface finishes by clearing chips

Probing Systems

Probing Systems

With the help of our highly advanced Wireless Intuitive Probing System (WIPS), we are able to set up your job up to 5 times faster. WIPS allows us to quickly and easily define work offset coordinates, set tool length offsets, and perform in-process inspection, for both part inspection and tool breakage detection.

What this means for you:

- 5x Faster tool loading - saving you money

- 5x Faster part setting - saving you money

- Automated part inspection capabilties - ensure your parts are deadly accurate

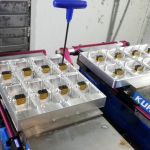

4 and 5 Axis Machining

The fastest way to increase the productivity of a milling center is to add a 4th or 5th axis rotary. The fully integrated rotary table indexers allows for complex multi-sided machining, yielding increased productivity and reduced setups.

- Reduces setups - saving you money

- Reduces part handling - saving you money

- Reduces overall machining time per part - saving you money

- Increases accuracy - improving quality

Contact us via email at Info@LockhartPrecision.ca or by phone (250) 715-7290

A few of our capabilities include but are not limited to:

- Gun Racks

- Rifle Cases

- Topless Glass Hand Railings

- Wrought Iron Fences and Rails

- Stainless Steel Cable Railings

- Plasma Cutting and Design

- Custom Built CNC Plasma Tables

- Custom Built CNC Router Tables

- Custom CNC Machines made to order

- Aluminum Roof Racks

- Aluminum and Stainless Steel Welding and Fabrication

- Marine Fuel Tanks

- Fishing Boats and Equipment Refitting

- Aluminum Fishing Rod Holders

- Aluminum Radar Arches

- Automatic Gate Systems

- Steel Shooting Targets

- Custom Aluminum Welding Truck Rig Boxes and Decks

and more!