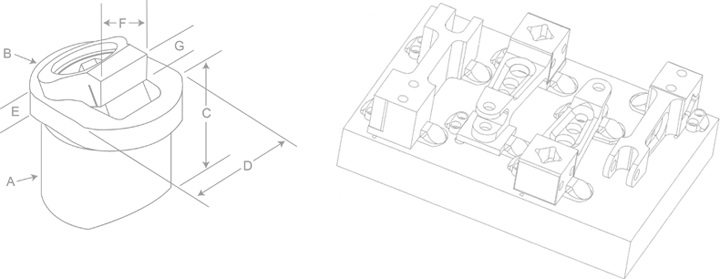

Dyna-Force® Clamps

The majority of the Dyna-Force® clamp is below the surface of the fixture which provides excellent clamp support and makes for a very low profile. The clamp jaw slides on an angle for positive downforce.

The clamp jaw is available with smooth or serrated faces.

The support surface of the Dyna-Force® clamp can be installed flush with the fixure plate or raised to hold the workpiece off the fixture, enabling drill-through.

- Incredible Clamping and Hold Down Power

- Low Profile, Compact Design

- 17-4 PH Stainless Steel

- Smooth or Serrated

- Stainless steel screws and retaining rings are available for EDM applications

PATENT NO. 5964458

|

|

Metric

Part

No. | | Clamp Jaw†

& Hardiness | A* | B | C | D | E | F | —

Min | G

Optimum | —

Max | Clamp

Travel | Drive

Screw | Key

Size | Max

Torque | Holding

Force | Replacement

Insert** |

|---|

28314

28318 |

|

Smooth 34RC

Serrated 44RC |

20.00 |

24.90 |

19.00 |

19.90 |

4.50 |

13.50 |

3.25 |

5.00 |

6.75 |

2.0 |

M6x12mm |

5mm |

7.3 (Ft/Lbs)

9.9 (N.m) |

2,000 (Lbs)

8896 (N.) |

28480 (smooth)

28482 (serrated) |

28320

28322 |

|

Smooth 34RC

Serrated 44RC |

25.00 |

29.90 |

24.00 |

24.90 |

5.00 |

15.00 |

4.50 |

6.50 |

8.25 |

2.2 |

M8x16mm |

6mm |

17.6 (Ft/Lbs)

23.9 (N.m) |

2,600 (Lbs)

11565 (N.) |

28484 (smooth)

28486 (serrated) |

28324

28328 |

|

Smooth 34RC

Serrated 44RC |

30.00 |

37.90 |

29.00 |

29.90 |

7.00 |

20.00 |

4.50 |

7.50 |

10.75 |

3.8 |

M10x18mm |

8mm |

35.3 (Ft/Lbs)

41.9 (N.m) |

3,200 (Lbs)

14234 (N.) |

28488 (smooth)

28490 (serrated) |

†Smooth jaw only will have relief cut

*Body diameter

**Includes screw and retaining ring

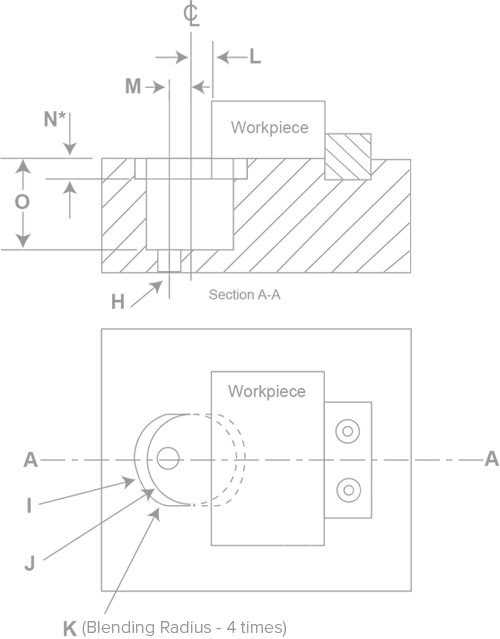

Dyna-Force® Installation

- Bore ℄ of the hole "L" distance from edge of workpiece.

- Drill and tap "H" to mount clamp in pocket.

- Machine counter bore if recessing clamp into fixture.

- Provide a back stop to locate the part.

|

| NOTES: |

- "N*" – To have rest pad flush with fixture, use the dimension provided. To have the

rest pad above the fixture surface, reduce the depth accordingly.

- For dimensions I and J, use a tolerance of +.1/-0mm. For dimension L and O,

use +.1/-.1mm.

|

|

|

Height of Jaw in Relation to ℄ of bore

from edge of workpiece.

Height of Jaw

G | 20mm

L | 25mm

L | 30mm

L |

|---|

| 3.25 |

5.91 |

|

|

| 3.50 |

5.77 |

|

|

| 3.75 |

5.62 |

|

|

| 4.00 |

5.48 |

|

|

| 4.25 |

5.33 |

|

|

| 4.50 |

5.19 |

6.81 |

8.78 |

| 4.75 |

5.05 |

6.66 |

8.63 |

| 5.00 |

4.90 |

6.52 |

8.49 |

| 5.25 |

4.76 |

6.37 |

8.35 |

| 5.50 |

5.61 |

6.23 |

8.20 |

| 5.75 |

4.47 |

6.08 |

8.06 |

| 6.00 |

4.32 |

5.94 |

7.91 |

| 6.25 |

4.18 |

5.80 |

7.77 |

| 6.50 |

4.03 |

5.65 |

7.62 |

| 6.75 |

3.89 |

5.51 |

7.48 |

| 7.00 |

|

5.36 |

7.34 |

| 7.25 |

|

5.22 |

7.19 |

| 7.50 |

|

5.07 |

7.05 |

| 7.75 |

|

4.93 |

6.90 |

| 8.00 |

|

4.78 |

6.76 |

| 8.25 |

|

4.64 |

6.61 |

| 8.50 |

|

|

6.47 |

| 8.75 |

|

|

6.33 |

| 9.00 |

|

|

6.18 |

| 9.25 |

|

|

6.04 |

| 9.50 |

|

|

5.89 |

| 9.75 |

|

|

5.75 |

| 10.00 |

|

|

5.60 |

| 10.25 |

|

|

5.46 |

| 10.50 |

|

|

5.31 |

| 10.75 |

|

|

5.17 |

Example: 20mm clamp when CL of bore is 4.90mm from edge of workpiece

(L – see drawing on left): jaw height is 5.00mm

|

| Part Number | H | I | J | K | L | M | N | O |

|---|

| 28314 |

M5 or 10-24 |

25.00 |

20.00 |

6.00 |

4.90 |

5.00 |

4.50 |

20.00 |

| 28318 |

M5 or 10-24 |

25.00 |

20.00 |

6.00 |

4.90 |

5.00 |

4.50 |

20.00 |

| 28320 |

M6 or 1/4-20 |

30.00 |

25.00 |

6.50 |

5.65 |

6.00 |

5.00 |

25.00 |

| 28322 |

M6 or 1/4-20 |

30.00 |

25.00 |

6.50 |

5.65 |

6.00 |

5.00 |

25.00 |

| 28324 |

M8 or 5/16-18 |

38.00 |

30.00 |

8.00 |

7.05 |

7.50 |

7.00 |

30.00 |

| 28328 |

M8 or 5/16-18 |

38.00 |

30.00 |

8.00 |

7.05 |

7.50 |

7.00 |

30.00 |